- #STM32 NUCLEO DEVELOPMENT BOARD UPGRADE#

- #STM32 NUCLEO DEVELOPMENT BOARD SOFTWARE#

- #STM32 NUCLEO DEVELOPMENT BOARD SERIES#

LordNothing on Protect Vintage Gear With Easy Capacitor Reforming.Chris Maple on Navy Program PUMPs Up Hopes For Magnetic Propulsion.effgee on C++17’s Useful Features For Embedded Systems.ginandbacon on Why Did The Home Assistant Future Not Quite Work The Way It Was Supposed To?.Paul on This Vending Machine Is For The Birds.

#STM32 NUCLEO DEVELOPMENT BOARD UPGRADE#

Upgrade pi-top on Chatting About The State Of Hacker-Friendly AR Gear.

#STM32 NUCLEO DEVELOPMENT BOARD SOFTWARE#

Posted in ARM, Microcontrollers, Software Development Tagged bare metal, embedded development, stm32 Post navigationĭon’t put the power planes on the outside of a 4 layer PCB.Ĥ layer PCB’s are much easier to route and are likely to improve the PCB design and reduce EMI compared t 2 layer PCB’s, but putting the GND plane on the outer layer is a bad idea for a lot of reasons.įirst, you have your parts soldered on the outside, which means you can’t have a continuous GND plane anymore.Ī lot of the benefits of a 4 layer PCB are from the closeness of the inner layers to the outside layers, there is just a thin prepreg between them, and this reduces the loop inductance significantly compared having the whole PCB (1.5mm) between the two layers.

#STM32 NUCLEO DEVELOPMENT BOARD SERIES#

For even more on the subject, you may like our STM32 Bootcamp series on bare-metal STM32 programming. While initially more time consuming, working close to the metal provides a good deal of additional insight into, and control over, hardware operations. We move on to increasingly advanced topics like timers, interrupts, UART output, debuggers, and even configuring an embedded web server to expose a complete device dashboard. The demonstration continues with setup and use of necessary tools such as the compiler, linker, and flasher.

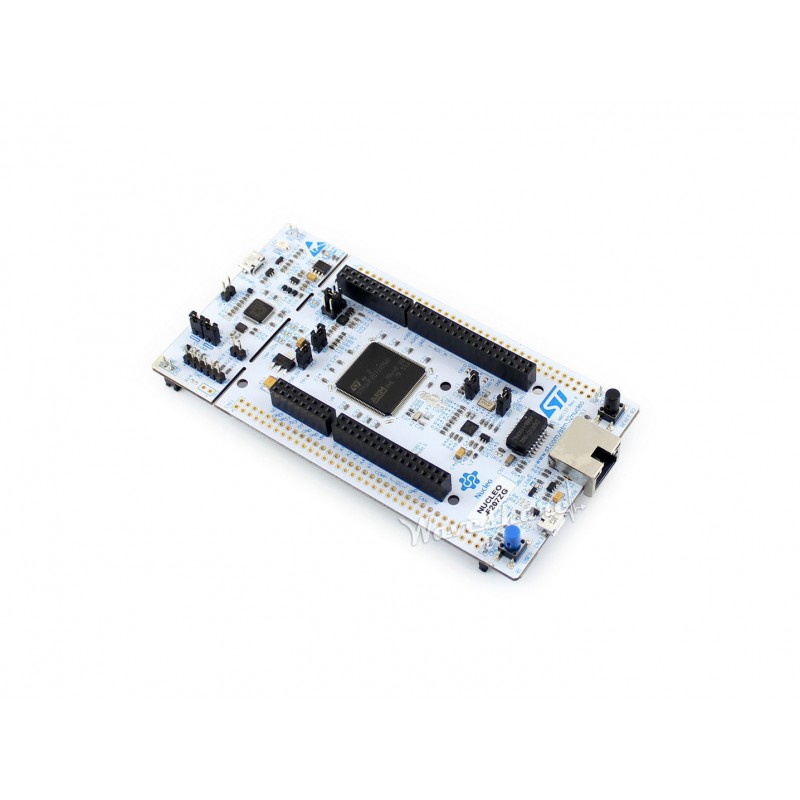

The guide walks us through writing up a minimal firmware program from boot vector to blinking an LED connected to an I/O pin. aptly defines this as programming the microcontroller “using just a compiler and a datasheet, nothing else.” His guide starts at the very foundation by examining the processor’s memory map and registers including locations for memory mapped I/O pins and other peripherals. When we forego these abstractions and program directly on the microprocessor or microcontroller, we’re working on the bare metal. For example, we often start projects already standing on the shoulders of various libraries, boot loaders, and integrated development tools. Even in the world of embedded programming, were things are generally quite low-level (close to the metal), we’ve grown accustomed to a good amount of hardware abstraction. This generally applies to programming BIOS, hardware drivers, communication drivers, elements of the operating system, and so forth. In the realm of computer systems, bare-metal programming most often refers to programming the processor without an intervening operating system. While the general concepts should be applicable to most any microcontroller, s examples specifically relate to the Nucleo-F429ZI development board featuring the ARM-based STM32F429 microcontroller. Put together this epic guide for bare-metal microcontroller programming.

0 kommentar(er)

0 kommentar(er)